Semi-trucks have rapidly turned into the life force of our existence. They deliver most of our favorite online items to us. However, ask any semi-truck driver, and he shall tell you about the problems that he might be facing.

The most significant issue with trucks is that they need to be driven over long distances. Therefore, the driver might have to stay in his truck for the entire day. Nowadays, most semi-trucks come with cabins so that the drivers can rest.

Installing semi-truck power inverter

The cabin has a refrigerator, microwave, bed, and other equipment. Undoubtedly, installing an inverter becomes essential to power the appliances while you are on the move. An inverter allows you to use cooking appliances, a travel cooler, watch television while you halt, and recharge your computer.

So, if you know how to install power inverter in a semi-truck, it will benefit you in multiple ways. The inverter can help you to cook your meals thus maintaining your general health. Eating regularly at truck stop buffets and fast food restaurants might result in the deterioration of your health, and you might end up spending a lot of money on unhealthy food. Moreover, having a power inverter can help you in playing video games or watching a movie on your DVD when you are not working.

This article highlights the factors affecting the installation of a power inverter and how it can be installed in a semi-truck. Read on to know how the installation of a power inverter can make your semi-truck comfortable.

Factors affecting the installation of a power inverter

Different size of power inverter

-

- Size of the inverter: You should pick a power inverter based on the size of your truck, power usage, and how you intend to use the inverter. You should make a list of all the appliances which need to be powered by the inverter and used together at a time. Your television takes up 250 watts, Microwave 1000 watts, DVD players 40 watts, laptops 95 watts, electric blankets 200 watts and portable heaters use up to 1500 watts. So, you should note down your energy consumption and then decide the best inverter for your use. You should also consider the surge power before installing the inverter. Whenever you switch on a device, the initial load is more than the usual power requirement. So, you need to check the surge rating of the inverter. It is usually twice the general power requirement on a high-quality inverter. Your inverter should be able to handle over five seconds of surge power before the inverter is shut down by the power draw.

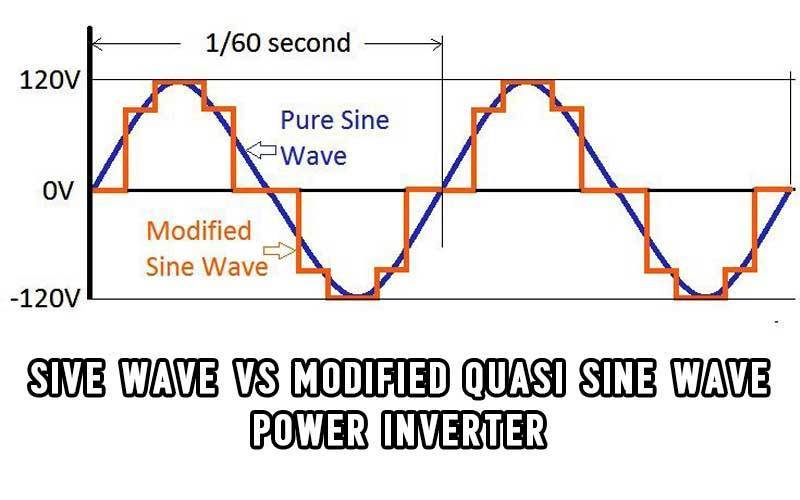

Sine wave vs modified quasi sine wave

- Type of electrical power- Sine wave or modified (quasi) sine wave: The inverters available in the market can be classified into two types, namely, a sine wave inverter and a modified sine wave inverter. Both kinds of inverters work excellently in a truck. However, if you are handling sensitive electronics or such appliances that are plugged into their chargers while being used, then sine wave is the ideal choice. The sine wave is similar to the power that you receive in your home. Thus, you can expect constant voltage without sudden elevations or drops.

- Durability: The inverter should last long after the warranty period. Do not opt for inverters that have a significantly lower cost than the other inverters in the market. Such inverters are of low-quality, and they are unable to withstand power surges. You should look for inverters that are which have been tested internally for quality control. Although inverters shut themselves down sometimes, good quality inverters do so without being damaged. If dust gets into the inverter, it can get overheated. A good quality inverter with high wattage will warn you that it is overheating. When you clean the inverter or switch its fan on, the problem of overheating shall be easily solved. You can easily differentiate between a high-quality inverter and a low-quality one based on how they handle a shutdown. A high-end inverter shuts down easily without having any ill-effects. A low-quality inverter might start malfunctioning after multiple overloads.

- Built-in battery charger: If you can use shore power to charge your batteries, then you should opt for a built-in battery charger. The electrical outlets which you find at multiple places such as truck stops, loading docks, and terminals are the sources of shore power. You can charge the batteries of your inverter while using the appliances that it powers. Shore power enhances the longevity of the cells of your inverter. You should always look for the low voltage disconnect feature in your inverter so that the truck can start without any hassles.If your semi-truck does not have an LVD, your inverter might let you run your electronics for a longer duration, but you shall not be able to start the truck.

Installing process of Power Inverter in Semi-Truck

How to install power inverter in semi-truck?

The installation of power inverters in semi-truck is straightforward. However, you should purchase a proper installation kit. You should also unbind the battery cables. Do this carefully so that the inverter does not get destroyed.

You should match the wattage and voltage on the inverter and the kit. Follow all the directions on the package and use heavy duty cables and good quality T-fuses.

Here’s how to install power inverter in semi-truck:

- Plan the job: It is crucial to plan out the job beforehand so that you do not mess up the cables and other equipment. You should have thorough information about the unit and the additional switches and outlets. You should place the inverter in an area that is dry, easy to access, and has proper ventilation. Ensure that you do not put any big objects near the inverter that might cause damage to the inverter during heavy braking. Make sure that you put the inverter close to the truck’s battery box. The path for the cables between the inverter and batteries should not have any hindrances. Check that you do not cause any damage to the underlying wiring and framework while boring the holes.

- Make the holes for the cable: Cut adequate holes for the cables and wiring by following the manufacturer’s instructions. You should line the holes with rubber grommets to protect them from grazing on the metal. Ensure that you remove any mat, carpet, or rugs on the area before boring the hole.

- Lay the cables: Since the battery of the inverter holds a lot of currents, it is better to get the ends installed professionally rather than doing it yourself. You can contact the inverter manufacturer or an electrical shop that has adequate crimping apparatus.

- Fix the fuse block: Although your manufacturer might claim that all the objects have internal safety systems, you should protect your inverter with a fuse on the positive Direct Current cable. The installation kits usually include the holder and the fuse that need to be mounted within the battery box. In case you need to buy them separately, you should pick such components which can handle the load of your inverter. While you are setting the holder, you should leave ample space so that the cables can be connected adequately.

- Mount your inverter: Ensure the removal of rugs, rubber mats, or padding so that there is proper ventilation. You can utilize the homemade templates or those provided in the inverter installation kit to bore the holes. Connect all the wires and cables to the inverter and then fix it with screws that are corrosion-proof. Make your inverter box secure by protecting it with a firmly mounted shield before the cargo box installation. You can use a stainless steel or aluminum sheet for added protection of the inverter from any massive objects that slide down while you are driving. Leave space around it so that it has optimal ventilation.

- Link the unit with the shore power receptacle: If your inverter comes with a shore power receptacle, you should find a spot where there is no wheel spray and it is accessible from the floor. You should use this spot for mounting the shore power receptacle. Ensure that you follow the manufacturer’s instructions correctly while connecting the cables of the inverter with the terminals of the receptacle. After you complete connecting the wires and the terminals, you need to coat them with a suitable electrical sealant.

- Join the remote switch with the system: You should place the remote in the sleeper because it is the place which you will occupy while using the inverter. The sleeper’s control panel usually has sufficient space for the switch. You can wrap the wires that are submerged with a split-poly loom to defend them against abrasion against other metals.

- Link all the wires with the unit and fix all the cables and wires: You should follow the manufacturer’s instructions to connect any cables that might have been left behind. You should begin with the positive cable so that the battery can be appropriately hooked. All the wires and cables should be protected with split-poly loom, and then the entire system should be secured with plastic wire ties.

Conclusion

After reading how to install power inverter in semi-truck, you are fully aware of the entire procedure. You only need to ensure that all the indicator lights, switches, and dials are working correctly after finishing the installation of the power inverter.