How Do You Test an IWE Solenoid? Ford f150 ISE Noises and Solutions

If your F150 makes rattling or grinding noises, it can be associated with a bad IWE or a vacuum leak at lower speed (20-40 mph)

What is a IWE

Ford’s Integrated Wheel End (IWE) system is what locks and unlocks the front hubs when you change back and forth from 2WD and 4WD.

The system works off of vacuum and it uses vacuum to keep the hubs unlocked for 2WD and shuts off the vacuum to lock the front hubs for 4WD.

Anything vacuum-operated is prone to problems, and the IWE system isn’t an uncommon point of issues on any 4WD F150, regardless of engine option.

The IWE system is made up of four basic parts:

The IWE Solenoid/Valve Assembly , which controls the flow of vacuum when you change drives.

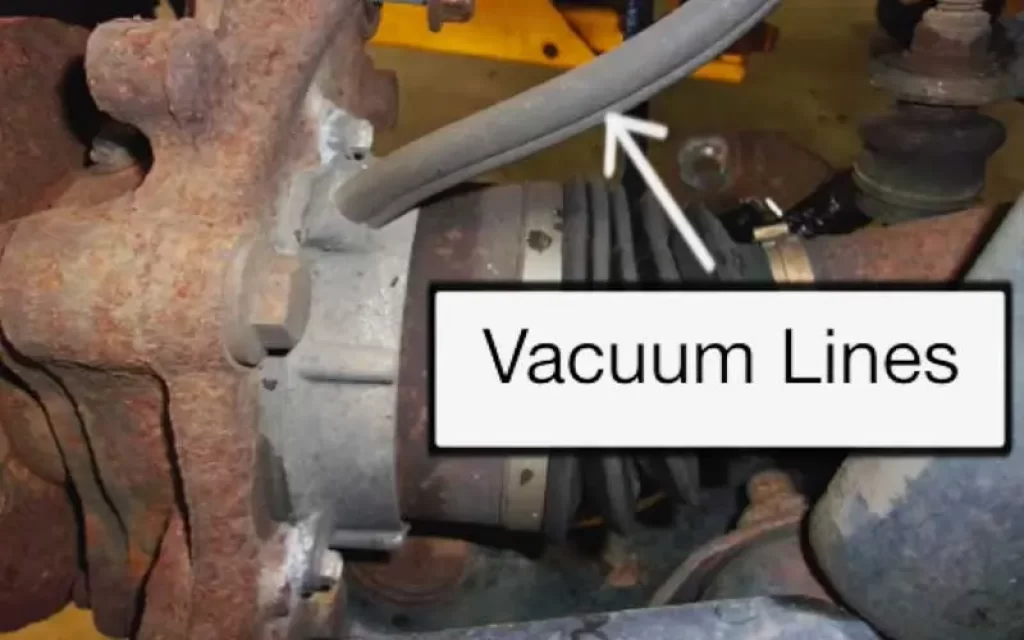

The IWE actuators; the IWE Vacuum Line; Your front wheel hubs though not technically part of the IWE system, they play a role can suffer during an IWE failure.

When the IWE system starts to fail, the first tell-tale sign is a grinding sound in 2WD, usually only under certain conditions when it first starts, but gets progressively worse.

The grinding is generally caused by the actuators not getting enough vacuum to disengage completely with the hub, and while that sounds simple, there could be several causes.

When the system is working correctly, vacuum is placed on the system unlocking the hubs while the truck is running.

When shifting to 4WD vacuum is released, locking in the hubs. A vacuum leak at any part of the system can cause failure.

When the engine is started and running, vacuum is exerted on the entire system, unlocking the IWE actuators.

When the engine is turned off or 4WD is engaged (either by floor shifter or dial selector) vacuum is released by the IWE solenoid to the actuators at the wheels.

So vacuum to the actuators at the wheel unlocks the hubs for 2WD and release of vacuum by the solenoid locks them for 4WD.

When the vacuum builds when the engine is started, the vacuum from the intake via a vacuum line exerts vacuum on the entire IWE system all the way to the actuators.

The first check valve locks the vacuum at the highest vacuum that is exerted from the engine from that check valve down. The vacuum box holds the highest vacuum exerted.

The second check valve located right before the IWE solenoid holds the highest vacuum to the actuators from what has been exerted from the engine.

As you start to understand the vacuum system and series of check valves, you will see that the vacuum box that is located between the two check valves does in fact act as a reserve.

When you engage the 4WD, vacuum is released by the solenoid and locks the line from draining back.

This process allows the lines and vacuum box between the two check valves to hold the current highest vacuum even though the engine vacuum is constantly changing.

When 4WD is disengaged, the solenoid is opened back up, the high vacuum from the reserve is used to exert vacuum on the lines to the actuators, unlocking them.

When this little bit of vacuum is lost in the reserve it is then rebuilt from the engine when vacuum is increased from the intake.

Working correctly without any leaks always ensures a high enough vacuum to keep the actuators unlocked when you’re in 2WD, or unlocking quickly when shifting from 4WD to 2WD.

A leak in vacuum somewhere in the system, will allow the actuators to possibly try to engage or close to it when not needed.

That will give you the grinding or whining noise of the gears of the actuators trying to mesh together at highway speeds.

Read Also: What Fuel Should I Use In My f-150 Ecoboost

Where is IWE located?

You need to remove the wheel, disconnect the spindle from the upper ball joint and then disconnect the IWE that is located on the back side of the spindle.

Read Also: Transmission Shift Solenoid Test

How do you test IWE vacuum lines

To test the vacuum system, get a good vacuum pump with a gauge on it, about $60 (or cheaper) in many stores.

If you try to shift into 4WD and it will not engage, most likely your solenoid is not working and releasing the vacuum to the actuators and engaging the hubs.

Replace the solenoid. This might happen because of the early design of the IWE solenoid which lets water run off the cowl right down on top of the solenoid, possibly shorting it out.

The new style solenoids have a rain cover on them to prevent this. This is all being said as long as you know your shift motor on the side of the transfer case is working properly.

If you are in 4WD and it will not shift out, the solenoid is not opening back up to let vacuum release the actuators. Replace the solenoid.

If you hear a grinding or whining of gears at certain speeds or loads you probably have leak in your vacuum system somewhere and your vacuum is dropping In that case check the following.

One wheel at a time unplug the double vacuum hoses from the actuators at the wheel located behind the steering knuckle.

Put your vacuum pump on the big hose fitting and pump up the pump. If it is working correctly you will be able to build up the vacuum and it will hold.

A vacuum loss of 1 lb over 1 minute is acceptable. If you can not build a vacuum or it leaks down very fast, the seals on the actuator are shot and the actuator needs to be replaced.

Next check your lines from the solenoid to the actuators at the wheel. Pull the double vacuum line off the solenoid.

Pull the double vacuum line off of both actuators at the wheels. Plug the hoses at the wheels.

At the double hose that you took off the solenoid, trace the lines, you want the line that goes down to the wheels, not to the intake.

Take your pump and connect it to the line end from the solenoid that goes to the wheels. Pump the pump up and see if the vacuum on the gauge holds.

If it does not and leaks down, you have a leak in your lines between the solenoid and the actuators.

Check the lines very thoroughly from the solenoid to the wheels, it’s hard to get to some of the lines, but they all need to be checked, look for cracks or breaks.

Replace the lines with factory ones from Ford

Read Also: Air in Brake Line Symptoms

Conclusions

Follow those step by step instructions and you can replace your IWE. It’s not that difficult but you need to be handy and you need proper tools. If you don’t feel comfortable with the DIY procedure, please ask the help of a mechanic.